Last updated on January 7th, 2022 at 02:27 pm

[RICH_REVIEWS_SNIPPET category=”all”]

Aircraft Aerodynamics, Structures and Systems (3811 Questions)

Category B2 – Aircraft Aerodynamics Exams ( 128 questions 180 min),

[pdf-embedder url=”https://easapart66.academy/wp-content/uploads/securepdfs/2020/01/easa_part_66_academy-Ch03.pdf” title=”easa_part_66_academy Ch03″]

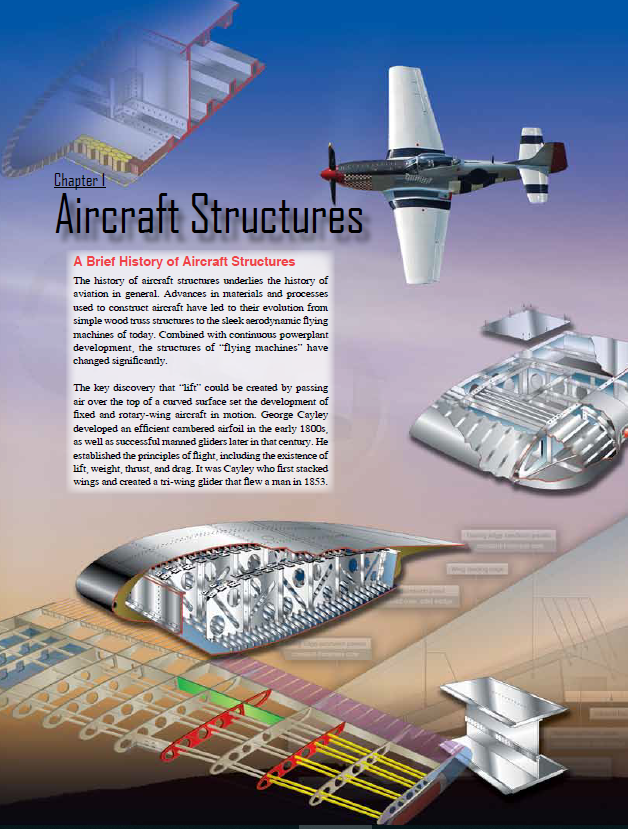

Chapter 01: Aircraft Structures (70 pages),

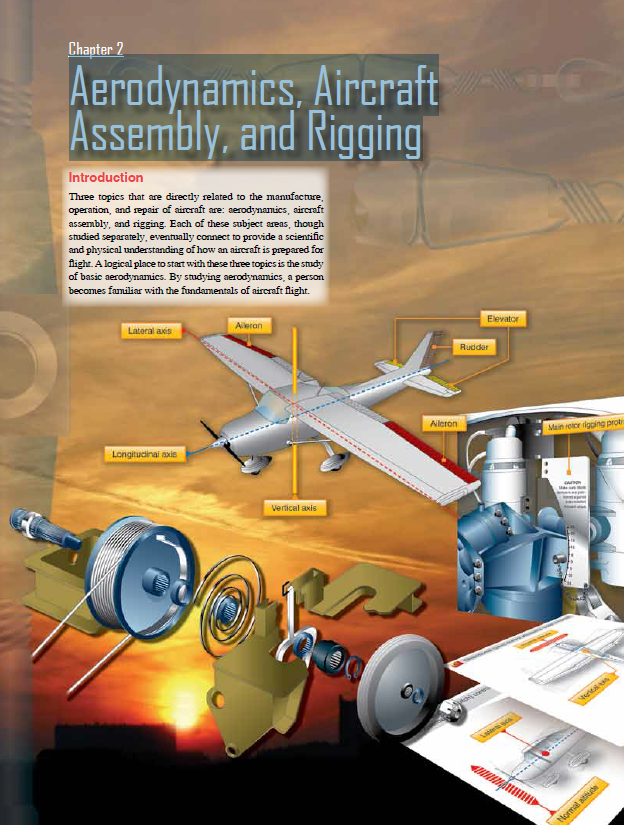

Chapter 02: Aerodynamics, Aircraft Assembly, and Rigging (70 pages),

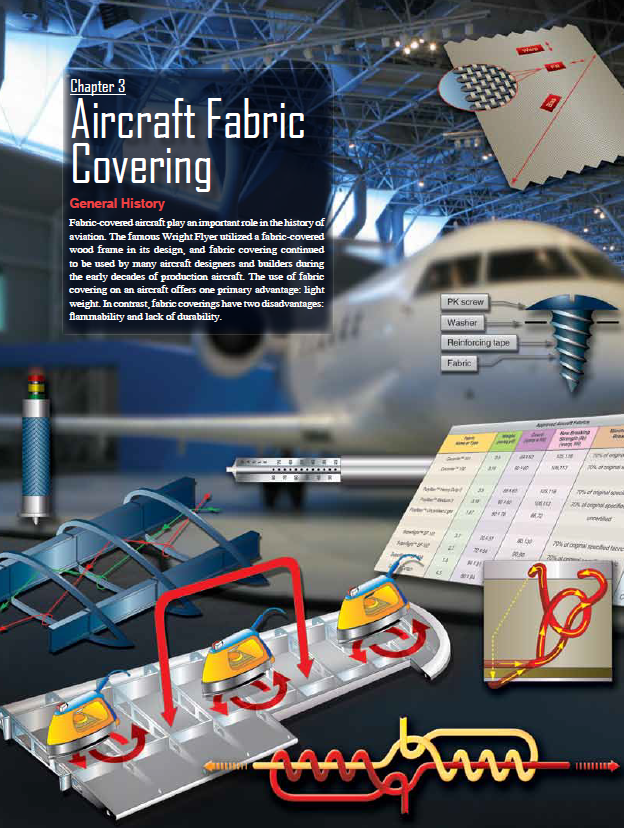

Chapter 03: Aircraft Fabric Covering ( 24 pages),

Chapter 04: Aircraft Metal Structural Repair ( 114pages),

Chapter 05: Aircraft Welding ( 38 pages),

Chapter 06: Aircraft Wood and Structural Repair ( 28 pages),

Chapter 07: Advanced Composite Material ( 58 pages),

Chapter 08: Aircraft Painting and Finishing ( 22 pages),

Chapter 09: Aircraft Electrical System ( 106 pages),

Chapter 10: Aircraft Instrument Systems (86pages),

Chapter 11: Communication and Navigation (78 pages),

Chapter 12: Hydraulic and Pneumatic Power Systems (54 pages),

Chapter 13: Aircraft Landing Gear Systems (96 pages),

Chapter 14: Aircraft Fuel System (62 pages),

Chapter 15: Ice and Rain Protection (32 pages),

Chapter 16: Cabin Environmental Control Systems (62 pages),

Chapter 17: Fire Protection Systems (22 pages),

Aircraft Fabric Covering

Fabric covered aircraft play an important role in the history of aviation. The famous Wright Flyer utilized a fabric-covered wood frame in its design, and continued to be used by many aircraft designers and builders during the early decades of production aircraft. The use of fabric covering on an aircraft offers one primary advantage: light weight. In contrast, fabric coverings have two disadvantages: flammability and lack of durability.

Aircraft Fabric Covering

A Technical Standard Order (TSO) is a minimum performance

standard issued by the FAA for specified materials, parts,

processes, and appliances used on civil aircraft. For example,

TSO-15d, Aircraft Fabric, Grade A, prescribes the minimum

performance standards that approved aircraft fabric must

meet. Fabric that meets or exceeds the TSO can be used as a

covering. Fabric approved to replace Grade-A cotton, such as

polyester, must meet the same criteria. TSO-15d also refers to

another document, Society of Automotive Engineers (SAE)

Aerospace Material Specification (AMS) 3806D, which details

properties a fabric must contain to be an approved fabric for

airplane cloth. Lighter weight fabrics typically adhere to the

specifications.

Fabric

Fabric strength is a major factor in the airworthiness of

an aircraft. Fabric is considered to be airworthy until it

deteriorates to a breaking strength less than 70 percent of

the strength of the new fabric required for the aircraft. For

example, if an aircraft was certificated with Grade-A cotton

fabric that has a new breaking strength of 80 pounds, it

becomes unairworthy when the fabric strength falls to 56

pounds, which is 70 percent of 80 pounds.

Please support us with rating this article.

[RICH_REVIEWS_FORM category=”all”]