Last updated on April 27th, 2022 at 03:21 am

EASA Part 66 Module 7

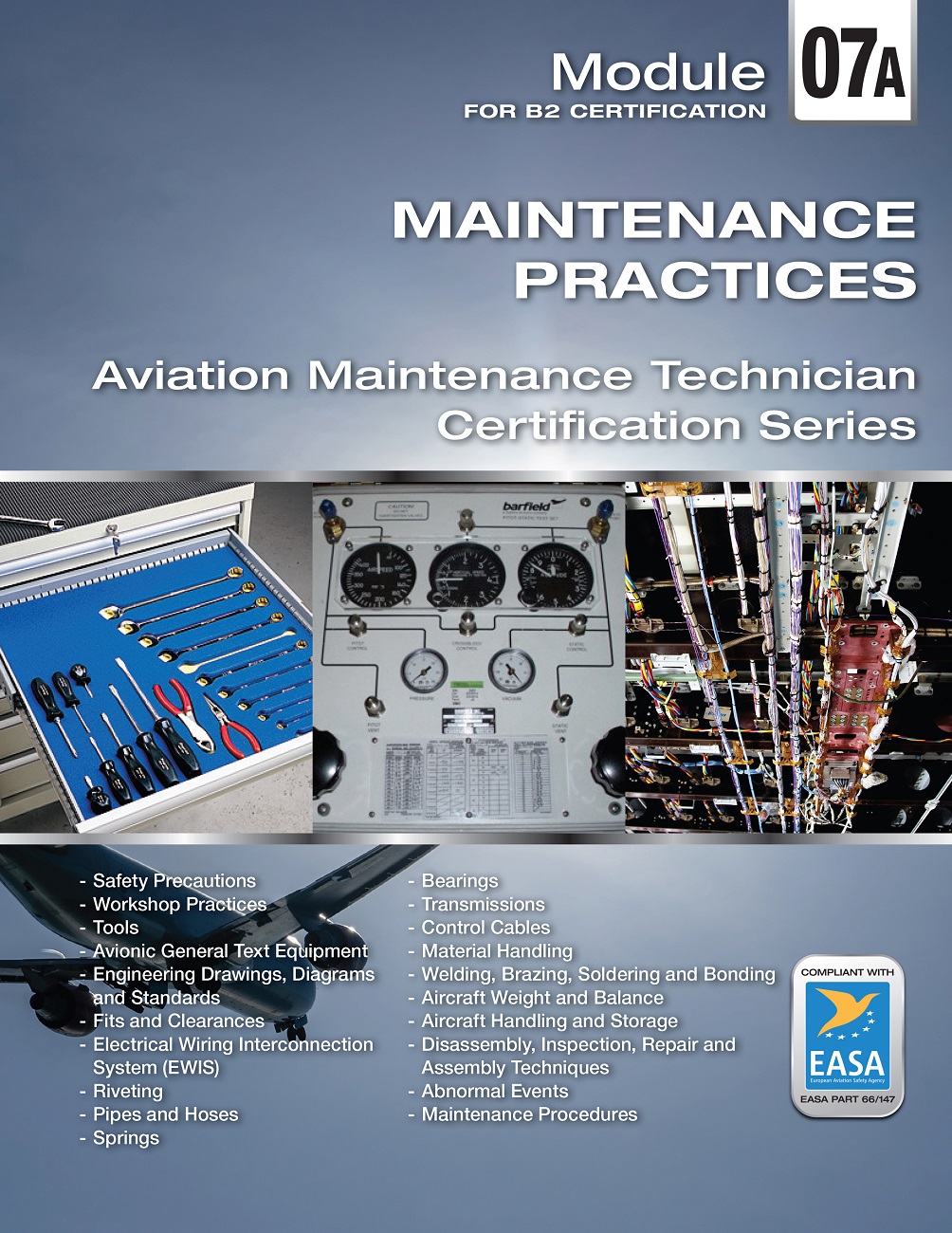

Module 7 Maintenance Practice.

Maintenance Practice Book Sample Pages

[pdf-embedder url=”//easapart66.academy/wp-content/uploads/securepdfs/2019/05/module-7-sample.pdf”]

Book Store

Easa Part 66 Maintenance Practices (4664 Questions)

Sample – Maintenance Practices Exams ( 40 questions 30 min),

Category A – Maintenance Practices Exams ( 72 questions 90 min),

Category B1 – Maintenance Practices Exams ( 80 questions 100 min),

Category B2 – Maintenance Practices Exams ( 60 questions 75 min),

EASA Part 66 Module 7 Forum

Maintenance Practice Book Chapters

7.1 Safety Precautions – Aircraft and Shop

Safe working practices including around electricity, gases, oils, and chemicals. Action in case of fire and knowledge of extinguishing agents.7.2 Workshop Practices

Care and control of tools and materials; allowances and tolerances; standards of workmanship. Calibration of tools and equipment.7.3 Tools

Common hand tools and power tools; precision measuring tools; lubrication equipment and methods; functuion and use of electrical test equipment.7.4 Avionic Test Equipment

Operation, function, and use of avionic general test equipment.7.5 Engineering Drawings and Standards

Drawing types, symbols, dimensions, tolerances, and projections; title block information; microfilm and computerized presentations. ATA Specification 100. ISO, AN, MS, NAS, and MIL standards. Wiring and schematic diagrams.7.6 Fits and Clearances

drill sizes, classes of fits; schedules of fits and clearances for aircraft and engines; limits of bow, twist, and wear; standard methods for checking shafts, bearings, and other parts.7.7 Electrical Wiring Interconnection System (EWIS)

Continuity, insulation, and bonding techniques and testing. Use of hand and hydraulic crimp tools. Testing crimp joints. Connector pin removal and insertion. Co-axial cables, testing and installation. Identification of wire types, inspection criteria, and damage tolerance. Wire protection techniques; cable looming and support; cable clamps, protective sleeving including heat shrink and shielding.7.8 Riveting

Riveted joints, spacing and pitch. Tools for riveting and dimpling. Inspection of riveted joints.7.9 Pipes and Hoses

Bending, belling, and flaring aircraft pipes. Inspection and testing of pipes and hoses. Installation and clamping of pipes.7.10 Springs

Inspection and testing of springs.7.11 Bearings

Testing, cleaning and inspection of bearings. Lubrication requirements. Defects of bearings and their causes.7.12 Transmissions

Inspection of gears and backlash. Inspection of belts, pulleys, chains, and sprockets. Inspection of screw jacks, lever devices, push-pull rod systems.7.13 Control Cables

Swaging of end fittings. Inspection and testing of control cables. Bowden cables, aircraft flexible control systems.7.14 Material Handling

Sheet Metal: bend allowance, metal working, inspection. Composites: bonding environmental conditions, inspection.7.15 Welding, Brazing, Soldering, and Bonding

Soldering methods and inspection. Welding and brazing methods, and inspection. Bonding methods and inspection.7.16 Aircraft Weight and Balance

Center of gravity/balance limits and calculation and use of relevant documents. Preparation and weighing of aircraft.7.17 Aircraft Handling and Storage

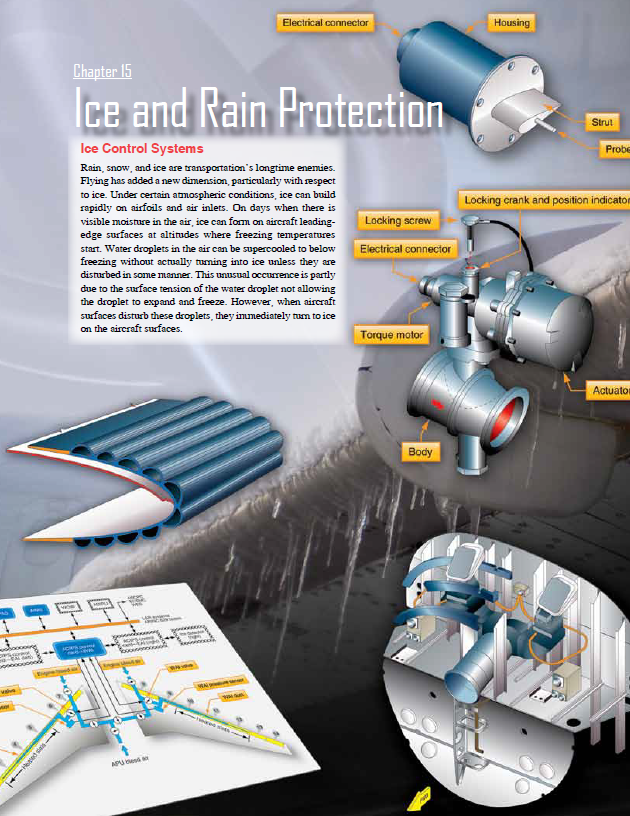

Aircraft taxiing, towing, and associated precautions. Aircraft storage methods. Refueling and defueling procedures. De-icing and anti-icing procedures. Electrical, hydraulic, and pneumatic ground supplies. Effects of environmental conditions on handling and operation.7.18 Disassembly, Inspection, Repair and Assembly Techniques

A) Defects and visual inspection; corrosion removal, assessment, and reprotection. B) general repair methods; aging, fatigue, and corrosion control programs. C)Non-destructive inspection including penetrant, radiographic, eddy current, ultrasonic, and boroscope methods. D) Disassembly and reassembly techniques. E) Troubleshooting techniques.7.19 Abnormal Events

Inspection following lightning strikes and HIRF penetration. Inspections following heavy landings and turbulence.7.20 Maintenance Procedures

Maintenance planning; modification procedures; stores procedures; certification/release procedures; interface with aircraft operations; inspection and quality control assurance; control of life limited procedures. Read more