Last updated on January 7th, 2022 at 02:27 pm

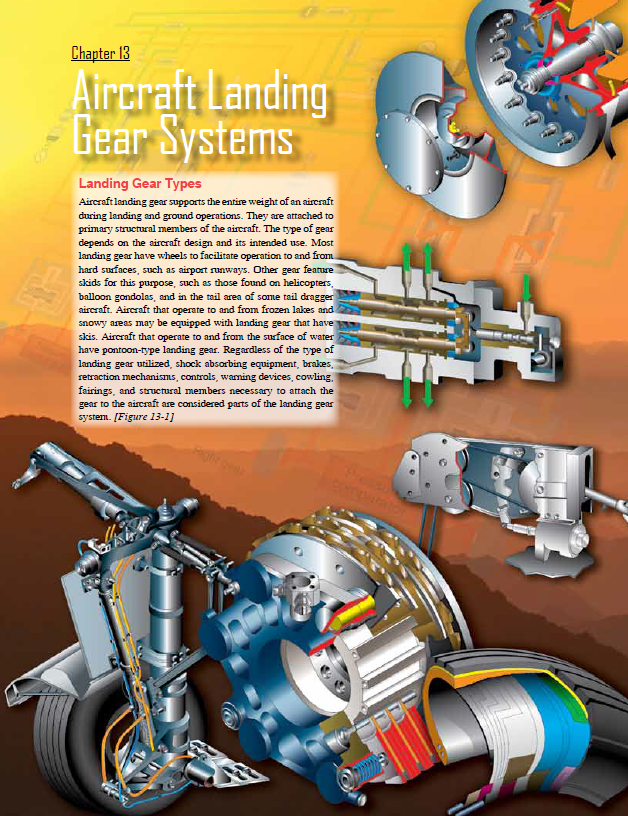

Aircraft Landing Gear Systems

Materials and Hardware (4164 Questions)

easa_part_66_academy Ch13Sample – Materials Exams ( 40 questions 30 min),

Category A – Materials and Hardware Exams ( 52 questions 65 min),

Category B1 – Materials and Hardware Exams ( 72 questions 90 min),

Category B2 – Materials and Hardware Exams ( 60 questions 75 min),

Category B3 – Materials and Hardware Exams ( 60 questions 75 min),

Chapter 01: Aircraft Structures (70 pages),

Chapter 02: Aerodynamics, Aircraft Assembly, and Rigging (70 pages),

Chapter 03: Aircraft Fabric Covering ( 24 pages),

Chapter 04: Aircraft Metal Structural Repair ( 114pages),

Chapter 05: Aircraft Welding ( 38 pages),

Chapter 06: Aircraft Wood and Structural Repair ( 28 pages),

Chapter 07: Advanced Composite Material ( 58 pages),

Chapter 08: Aircraft Painting and Finishing ( 22 pages),

Chapter 09: Aircraft Electrical System ( 106 pages),

Chapter 10: Aircraft Instrument Systems (86pages),

Chapter 11: Communication and Navigation (78 pages),

Chapter 12: Hydraulic and Pneumatic Power Systems (54 pages),

Chapter 13: Aircraft Landing Gear Systems (96 pages),

Chapter 14: Aircraft Fuel System (62 pages),

Chapter 15: Ice and Rain Protection (32 pages),

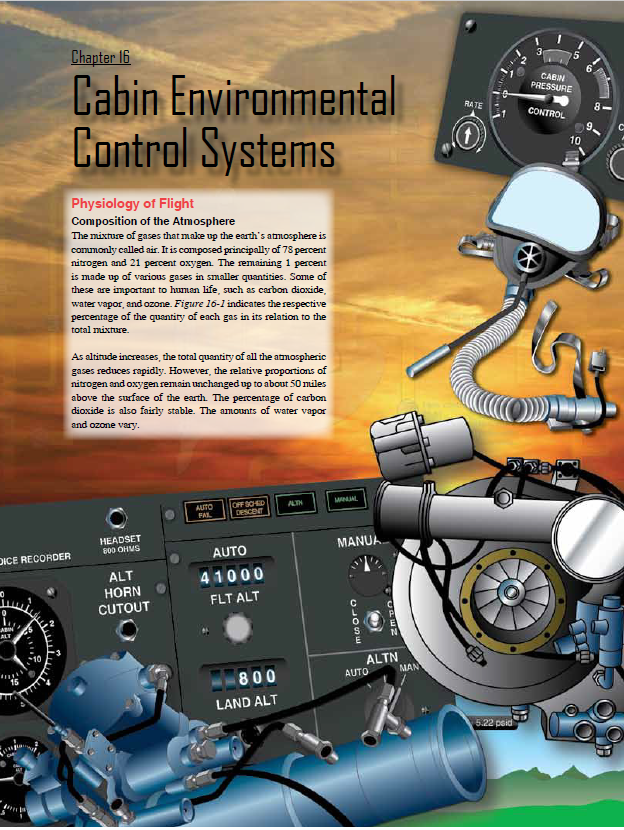

Chapter 16: Cabin Environmental Control Systems (62 pages),

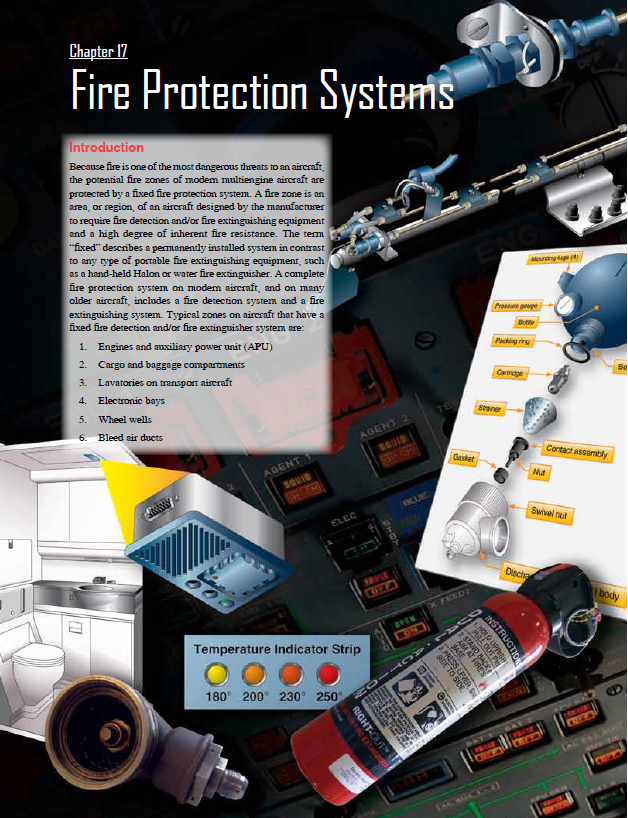

Chapter 17: Fire Protection Systems (22 pages),

Aircraft Landing Gear Systems

Numerous configurations of landing gear types can be aircraft Landing Gear Systems

found. Additionally, combinations of two types of gear are common. Amphibious aircraft are designed with gear that allow landings to be made on water or dry land. The gear features pontoons for water landing with extendable wheels aircraft for landings on hard surfaces. A similar system is used to allow the use of skis and wheels on aircraft that operate on both slippery, frozen surfaces and dry runways. Typically, the skis are retractable to allow use of the wheels when needed.

Figure 13-2 illustrates this type of landing gear.

NOTE: References to auxiliary landing gear refer to the aircraft Landing Gear Systems nose gear, tail gear, or outrigger-type gear on any particular aircraft. Main landing gear are the two or more large gear aircraft Landing Gear Systems located close to the aircraft’s center of gravity.

Landing Gear Arrangement Three basic arrangements of landing gear are used: tail wheeltype landing gear (also known as conventional gear), tandem landing gear, and tricycle-type landing gear.Tail Wheel-Type Landing Gear Tail wheel-type landing gear is also known as conventional gear because many early aircraft use this type of arrangement.

The main gear are located forward of the center of gravity, causing the tail to require support from a third wheel aircraft Landing Gear Systems assembly. A few early aircraft designs use a skid rather than a tail wheel. This helps slow the aircraft upon landing and provides directional stability. The resulting angle of the aircraft fuselage, when fitted with conventional gear, allows the use of a long propeller that compensates for older, underpowered engine design. The increased clearance of the aircraft Landing Gear Systems forward fuselage offered by tail wheel-type landing gear is also advantageous when operating in and out of non-paved runways. Today, aircraft are manufactured with conventional aircraft gear for this reason and for the weight savings accompanying the relatively light tail wheel assembly.

Please support us with rating this article.