Last updated on January 7th, 2022 at 02:27 pm

Aircraft Metal Structural Repair

[RICH_REVIEWS_SNIPPET category=”all”]

Aircraft Aerodynamics, Structures and Systems (3811 Questions)

Category B2 – Aircraft Aerodynamics Exams ( 128 questions 180 min),

[pdf-embedder url=”https://easapart66.academy/wp-content/uploads/securepdfs/2020/01/easa_part_66_academy-Ch04.pdf” title=”easa_part_66_academy Ch04″]

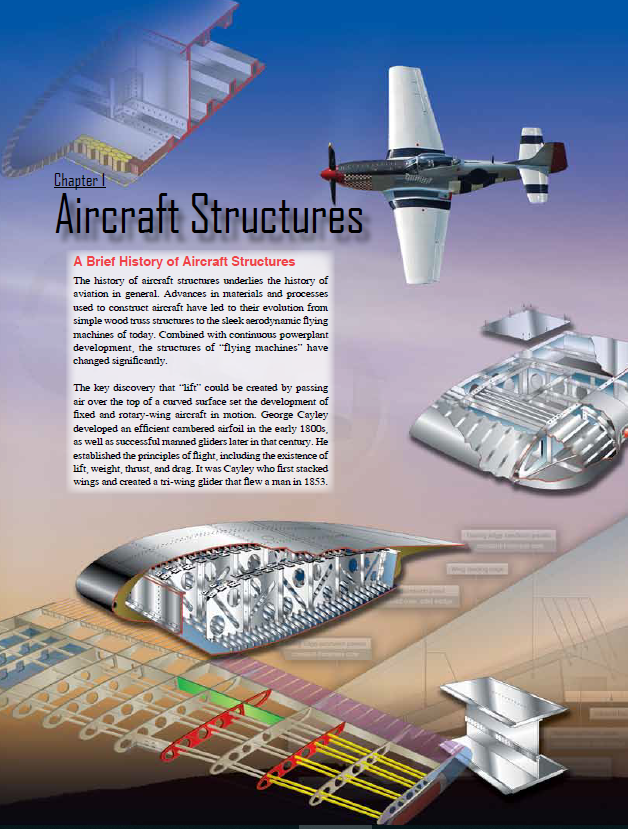

Chapter 01: Aircraft Structures (70 pages),

Chapter 02: Aerodynamics, Aircraft Assembly, and Rigging (70 pages),

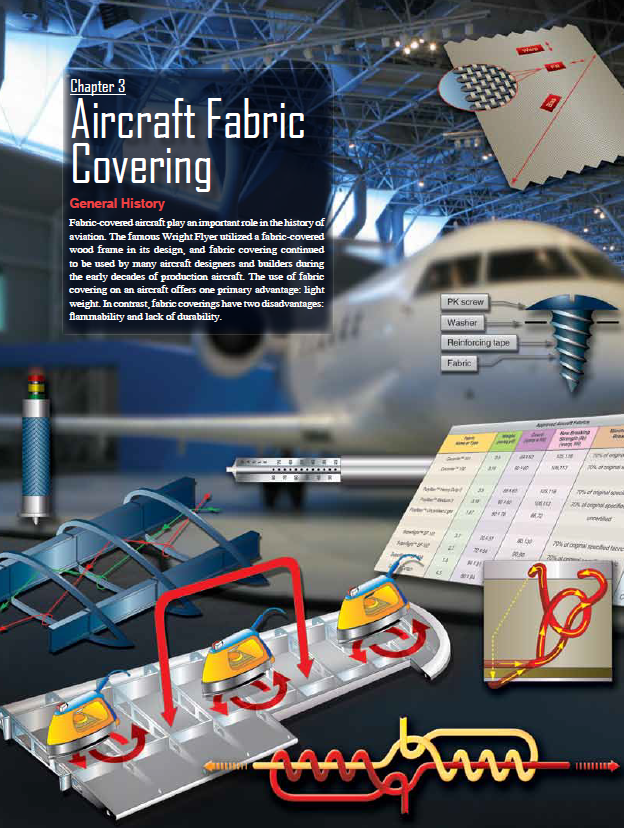

Chapter 03: Aircraft Fabric Covering ( 24 pages),

Chapter 04: Aircraft Metal Structural Repair ( 114pages),

Chapter 05: Aircraft Welding ( 38 pages),

Chapter 06: Aircraft Wood and Structural Repair ( 28 pages),

Chapter 07: Advanced Composite Material ( 58 pages),

Chapter 08: Aircraft Painting and Finishing ( 22 pages),

Chapter 09: Aircraft Electrical System ( 106 pages),

Chapter 10: Aircraft Instrument Systems (86pages),

Chapter 11: Communication and Navigation (78 pages),

Chapter 12: Hydraulic and Pneumatic Power Systems (54 pages),

Chapter 13: Aircraft Landing Gear Systems (96 pages),

Chapter 14: Aircraft Fuel System (62 pages),

Chapter 15: Ice and Rain Protection (32 pages),

Chapter 16: Cabin Environmental Control Systems (62 pages),

Chapter 17: Fire Protection Systems (22 pages),

Aircraft Metal Structural Repair

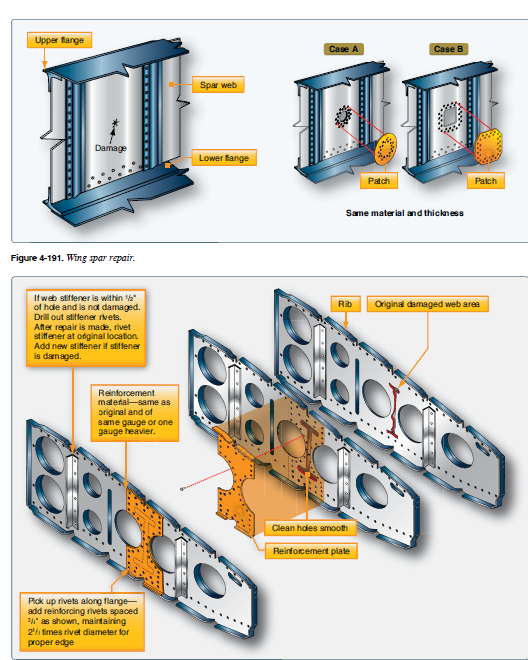

The satisfactory performance of an aircraft requires continuous maintenance of aircraft structural integrity. It is important that metal structural repairs be made according to the best available techniques because improper repair techniques can pose an immediate or potential danger aircraft metal structural repair.

The reliability of an aircraft depends on the quality of the design, as well as the workmanship used in making the repairs. The design of an aircraft metal structural repair is complicated by the requirement that an aircraft be as light as possible.

If weight were not a critical factor,FAA Airframe Handbook repairs could be made with a large margin of safety. In actual practice, repairs must be strong enough to carry all of the loads with the required factor of safety, but they must not have too much extra strength.

aircraft metal structural repair

For example, FAA Airframe Handbook a joint that is too weak cannot be tolerated, but a joint that is too strong can create stress risers that may cause cracks in other locations.

As discussed in Chapter 3, Aircraft Fabric Covering, sheet metal aircraft construction dominates modern aviation.

Generally, sheet metal made of aluminum alloys is used in airframe sections that serve as both the structure and outer aircraft covering, with the metal parts joined with rivets or other types of fasteners. Sheet metal is used extensively in many types of aircraft from airliners to single engine airplanes, but it may also appear as part of a composite airplane, such as in an instrument panel. FAA Airframe Handbook Sheet metal is obtained by rolling metal into flat sheets of various thicknesses ranging from thin (leaf) to plate (pieces thicker than 6 mm or 0.25 inch).The thickness of sheet metal, called gauge, ranges from 8 to 30 with the higher gauge denoting thinner metal. Sheet metal can be cut and bent into a variety of shapes.

Please support us with rating this article.

[RICH_REVIEWS_FORM category=”all”]