Last updated on January 7th, 2022 at 02:27 pm

Aircraft Advanced Composite Materials

[RICH_REVIEWS_SNIPPET category=”all”]

Aircraft Composite Materials (230811 Questions)

easa_part_66_academy Ch07Category A – Turbine Aeroplane Exams ( 108 questions 135 min),

Category B1 – Turbine Aeroplane Exams ( 140 questions 175 min),

Category A – Piston Aeroplane Exams ( 72 questions 90 min),

Category B1– Piston Aeroplane Exams ( 100 questions 125 min),

Category B3 – Piston Aeroplane Exams ( 60 questions 75 min),

Category A – Helicopter Aerodynamics Exams ( 100 questions 125 min),

Category B1– Helicopter Aerodynamics Exams ( 128 questions 160 min),

Category B2 – Aircraft Aerodynamics Exams ( 128 questions 180 min),

Chapter 01: Aircraft Structures (70 pages),

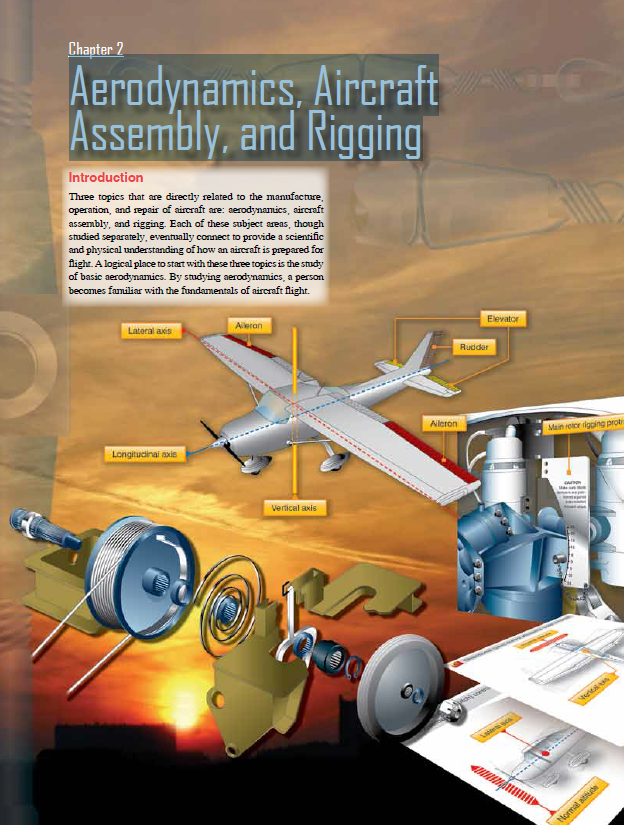

Chapter 02: Aerodynamics, Aircraft Assembly, and Rigging (70 pages),

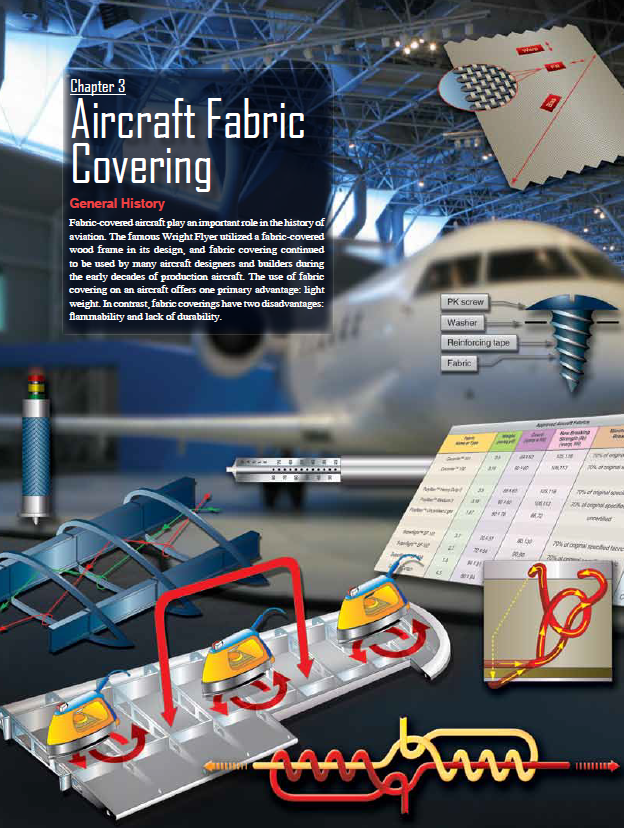

Chapter 03: Aircraft Fabric Covering ( 24 pages),

Chapter 04: Aircraft Metal Structural Repair ( 114pages),

Chapter 05: Aircraft Welding ( 38 pages),

Chapter 06: Aircraft Wood and Structural Repair ( 28 pages),

Chapter 07: Advanced Composite Material ( 58 pages),

Chapter 08: Aircraft Painting and Finishing ( 22 pages),

Chapter 09: Aircraft Electrical System ( 106 pages),

Chapter 10: Aircraft Instrument Systems (86pages),

Chapter 11: Communication and Navigation (78 pages),

Chapter 12: Hydraulic and Pneumatic Power Systems (54 pages),

Chapter 13: Aircraft Landing Gear Systems (96 pages),

Chapter 14: Aircraft Fuel System (62 pages),

Chapter 15: Ice and Rain Protection (32 pages),

Chapter 16: Cabin Environmental Control Systems (62 pages),

Chapter 17: Fire Protection Systems (22 pages),

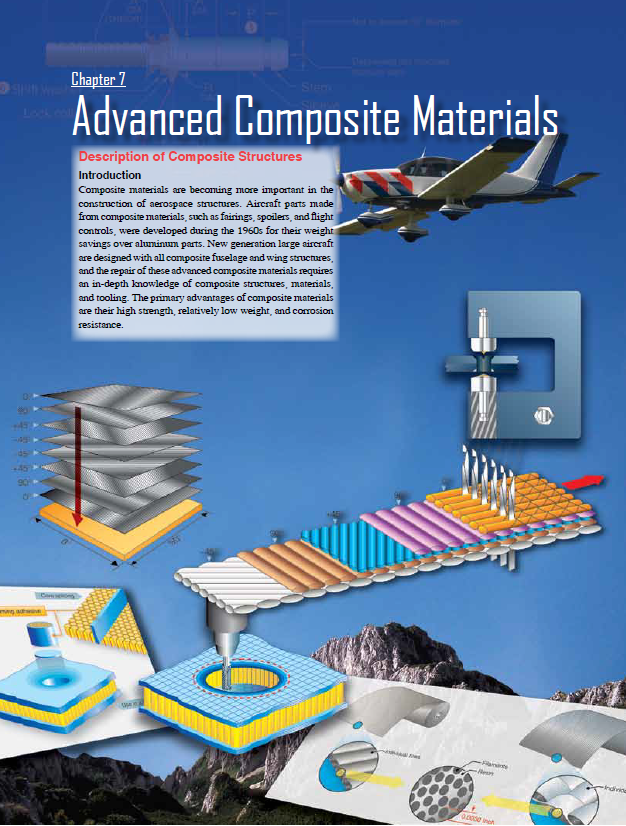

Aircraft Advanced Composite Material

Composite materials consist of a combination of materials Aircraft Composite Materials that are mixed together to achieve specific structural properties. The individual materials do not dissolve or merge Advanced Composite Material completely in the composite, but they act together as one.

Normally, the components can be physically identified as they Advanced Composite Material interface with one another. The properties of the composite Advanced Composite Material material are superior to the properties of the individual

materials from which it is constructed.

An Aircraft Composite Materials is made of a fibrous material Advanced Composite Material embedded in a resin matrix, generally laminated with fibers oriented in alternating directions to give the material strength Advanced Composite Material and stiffness. Fibrous materials are not new; wood is the most common fibrous structural material known to man.

Applications of composites on aircraft include:

• Fairings

• Flight control surfaces

• Landing gear doors

• Leading and trailing edge panels on the wing and stabilizer

• Interior components

• Floor beams and floor boards

• Vertical and horizontal stabilizer primary structure on large aircraft

• Primary wing and fuselage structure on new generation large aircraft

• Turbine engine fan blades

• Propellers

Major Components of a Laminate An isotropic material has uniform properties in all directions.

The measured properties of an isotropic material are independent of the axis of testing. Metals such as aluminum Advanced Composite Material and titanium are examples of isotropic materials.

A fiber is the primary load carrying element of the composite material. The composite material is only strong and stiff in the direction of the fibers. Unidirectional composites have Aircraft Advanced Composite Materials predominant mechanical properties in one direction and are said to be anisotropic, having mechanical and/or physical properties that vary with direction relative to natural reference axes inherent in the material. Components made from fiberreinforced Aircraft Composite Materials composites can be designed so that the fiber orientation produces optimum mechanical properties, but they can only approach the true isotropic nature of metals, such as aluminum and titanium.

Please support us with rating this article.

[RICH_REVIEWS_FORM category=”all”]