Last updated on January 7th, 2022 at 02:27 pm

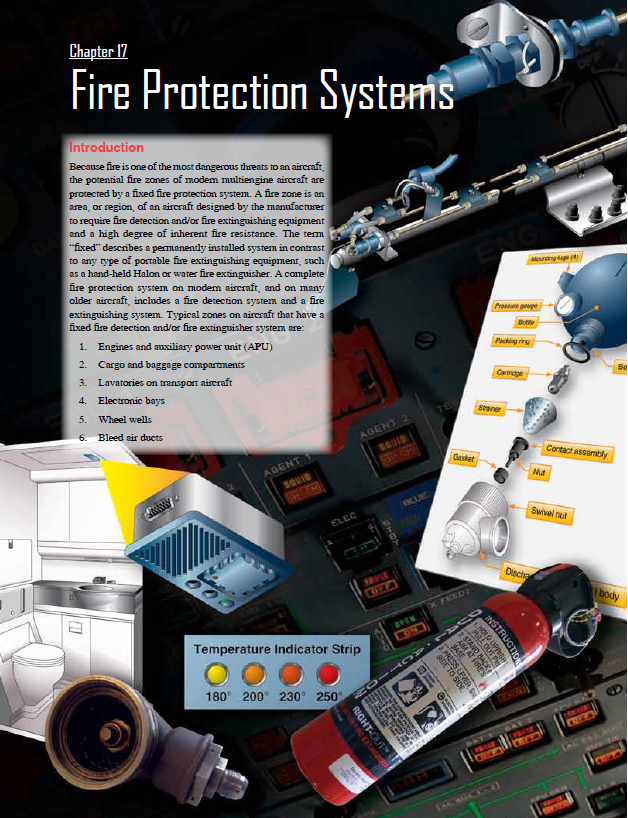

Aircraft Fire Protection Systems

[RICH_REVIEWS_SNIPPET category=”all”]

Easa Part 66 Maintenance Practices (4664 Questions)

Sample – Maintenance Practices Exams ( 40 questions 30 min),

Category A – Maintenance Practices Exams ( 72 questions 90 min),

Category B1 – Maintenance Practices Exams ( 80 questions 100 min),

Category B2 – Maintenance Practices Exams ( 60 questions 75 min),

[pdf-embedder url=”https://easapart66.academy/wp-content/uploads/securepdfs/2020/01/easa_part_66_academy-Ch17.pdf” title=”easa_part_66_academy Ch17″]

- Chapter 01: Aircraft Structures (70 pages),

- Chapter 02: Aerodynamics, Aircraft Assembly, and Rigging (70 pages),

- Chapter 03: Aircraft Fabric Covering ( 24 pages),

- Chapter 04: Aircraft Metal Structural Repair ( 114pages),

- Chapter 05: Aircraft Welding ( 38 pages),

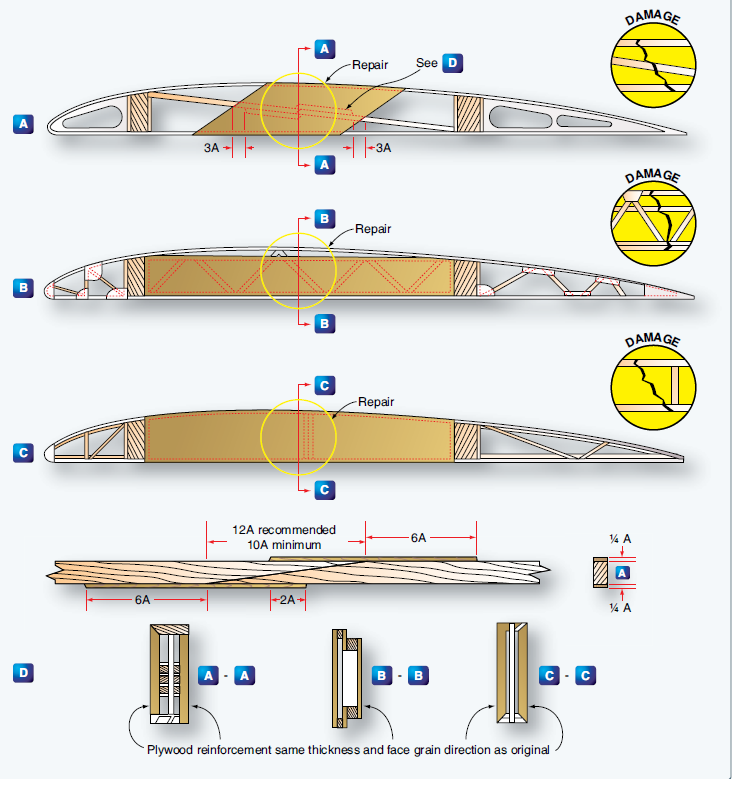

- Chapter 06: Aircraft Wood and Structural Repair ( 28 pages),

- Chapter 07: Advanced Composite Material ( 58 pages),

- Chapter 08: Aircraft Painting and Finishing ( 22 pages),

- Chapter 09: Aircraft Electrical System ( 106 pages),

- Chapter 10: Aircraft Instrument Systems (86pages),

- Chapter 11: Communication and Navigation (78 pages),

- Chapter 12: Hydraulic and Pneumatic Power Systems (54 pages),

- Chapter 13: Aircraft Landing Gear Systems (96 pages),

- Chapter 14: Aircraft Fuel System (62 pages),

- Chapter 15: Ice and Rain Protection (32 pages),

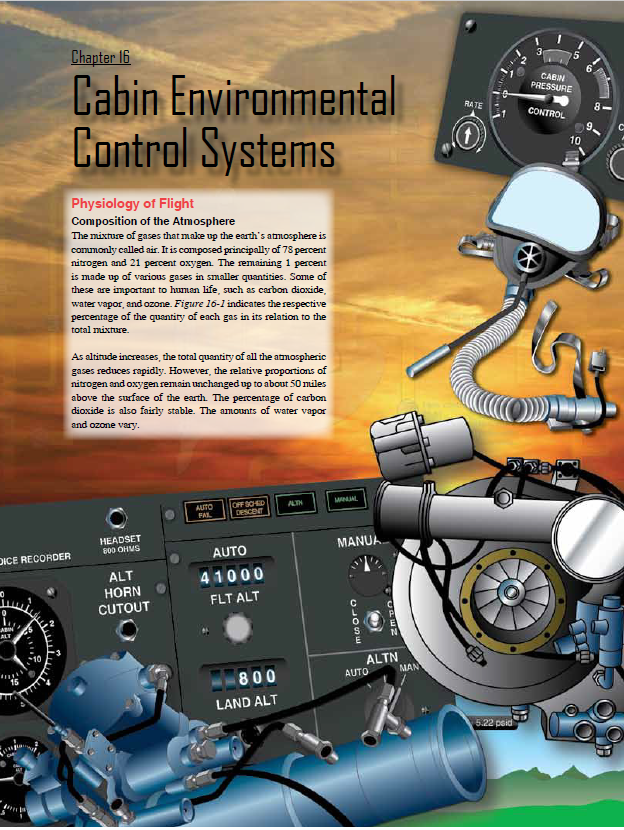

- Chapter 16: Cabin Environmental Control Systems (62 pages),

Aircraft Fire Protection Systems

To detect fires or overheat conditions, detectors are placed Fire Protection Systems in the various zones to be monitored. Fires are detected in reciprocating engine and small turboprop aircraft using one or more of the following:

1. Overheat detectors

2. Rate-of-temperature-rise detectors

3. Flame detectors

4. Observation by crewmembers

In addition to these methods, other types of detectors are Fire Protection Systems used in aircraft fire protection systems but are seldom used to detect engine fires. For example, smoke detectors are better suited to monitor areas where materials burn slowly Fire Protection Systems or smolder, such as cargo and baggage compartments.

Other types of detectors in this category include carbon monoxide detectors and chemical sampling equipment capable of detecting combustible mixtures that can lead to accumulations of explosive gases.

The complete aircraft fire protection systems of most large turbine-engine aircraft incorporate several of these different Fire Protection Systems detection methods.

Release valves are introduced on the compartments. A cartridge (squib) and frangible plate type valve are introduced in the outlet of the release valve gathering. Extraordinary congregations having solenoid-worked or physically worked seat-type valves are additionall accessible. Two kinds of cartridge circle discharge methods are utilized. Standard discharge type utilizes a slug driven by hazardous vitality to burst a divided conclusion plate.For high temperature or hermetically fixed units, a aircraft fire protection systems direct hazardous effect type cartridge is utilized that applies discontinuity effect to break a prestressed erosion safe steel stomach. Most compartments utilize ustomary metallic gasket seals that encourage renovation following wide scope of diagnostics is used to confirm the fire quencher specialist charge status. A straightforward visual sign measure is accessible, normally a helical bourdon-type marker that is vibration safe. measure switch outwardly demonstrates real holder pressure and furthermore gives an electrical sign if compartment pressure is lost, blocking the requirement for release pointers. A ground checkable stomach type low-pressure switch is generally

tilized on hermetically fixed holders. The Kidde framework has a temperature remunerated weight switch that tracks the compartment pressure varieties with temperatures by utilizing a hermetically fixed reference chamber.

Please support us with rating this article.

[RICH_REVIEWS_FORM category=”all”]